Written by Andrea Våge Aasen, Junior Ship Operator

What is fouling?

Hull fouling is the accumulation of unwanted marine organisms, such as barnacles, algae, slime, and mussels, on the surface of a ship's hull.

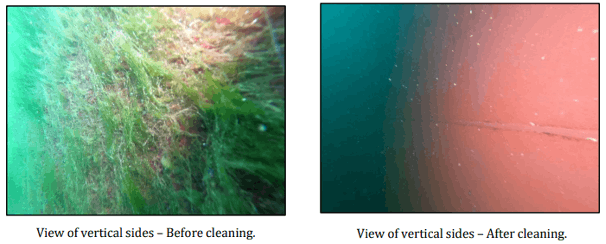

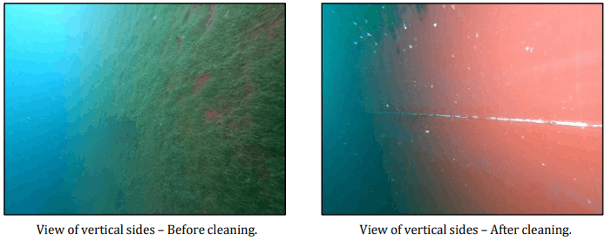

Odfjell uses the highest quality antifouling, and it gives results: This picture is from Bow Spring after five years. On this ship, the antifouling is SeaQuantum Classic S and Seamate M from Jotun.

The Limits of Anti-Fouling

Anti-fouling coatings remain the leading method for preventing fouling on the hull. The coating quality has improved significantly in recent years, but complete avoidance of fouling is still not possible. Additional and regular hull cleaning is essential for maintaining a clean hull over time.

All of Odfjell’s owned vessels are coated with a biocidal anti-fouling coating, acclaimed for its exceptional performance and low cost. These coatings contain a toxin (i.e. biocide) that gradually gets released into the water, creating a special layer around the hull’s surface that prevent biofouling species from attaching to the surface.

However, due to regulatory limitations, these biocidal coatings contain restricted levels of toxins, and the effectiveness decreases over time as the toxins deplete. Consequently, biofouling species will eventually begin to settle on the hull. To combat this, Odfjell’s Fleet Performance team actively monitor the fouling condition of all vessels.

In 1H 2024, Odfjell arranged 55 underwater services on our 70 operated vessels. Performance improvement and emissions reduction after a hull cleaning will vary depending on the particular vessel's fouling.

Results from 2023 indicate a reduction of between 6 and 8 tons of CO2 per day per vessel after a cleaning, which would add up to 600-800 tons of CO2 reduction in six months for one single vessel.

Advancing Hull Cleaning: From Divers to Remotely Operated Vehicles (-ROVs)

The hull cleaning process has significantly evolved over the years, transitioning from manual handheld equipment operated by divers to advanced technology utilizing remotely operated ROVs.

One of the most common practices for the past years has involved divers controlling a multiple-brush head device. However, these operations involve an inherent human risk and are harsh on the antifouling coating. In response, many vendors are now developing advanced ROVs that utilize high-pressure water jets instead of brushes.

Benefits of ROV Technology

This technological shift not only improves safety by eliminating the need for divers but also prolongs the lifespan of the anti-fouling, ensuring more efficient hull maintenance. ROVs are not only more effective and robust but also capable of operating in adverse weather conditions.

ROVs can operate simultaneously with cargo operations, allowing the vessel to set sail with a clean hull as soon as the cargo operations are complete. This ultimately reduces fuel consumption and increases efficiency.

“Our data shows that using ROVs can recover the cost of the hull cleaning already during the first sea leg,” Senior Fleet Performance Analyst Vegard Marken says.

Building Global Partnerships

Since initiating hull cleaning operations on Odfjell vessels, Odfjell has established solid relationships with several vendors worldwide. Having trusted partners in most of our frequent ports enables us to perform hull cleanings promptly upon detecting fouling. Solving the problem immediately ensures lower fuel consumption and more energy-efficient sailing at all times.

“I think it is important for Odfjell to use a combination of reliable partners for the underwater operations to de-risk these operations, while at the same time be open to test new technology and ways of working,” Marken comments.

The Environmental Impact of Hull Cleaning

Hull cleaning is important to remove biofouling from the hull and niche areas. However, it risks releasing invasive aquatic species into the environment when conducted in water.

Many marine species, transported in a ship’s ballast water or on its hull, may survive and establish a reproductive population in the host environment.

These species can outcompete native species and multiply into pest proportions, making them a significant threat to the world’s oceans and biodiversity conservation.

“Odfjell works actively to reduce our negative environmental footprints as much as possible. It is also believed that more and more countries will impose regulations on what kind of pollution to allow in their waters. If we manage to stay in front of the regulation and already now can use technology to reduce our impact as much as possible, we are in a good place,” Marken says.

The issue of the transfer of invasive aquatic species through ships' biofouling was first brought formally to IMO’s attention in 2006. It was agreed that the biofouling issue should be handled more effectively as scientific and technological advances were made.

IMO has also introduced procedures for reactive cleaning: hull cleanings should strive for effective collection and use appropriate technology to capture all biofouling material and waste and adapt procedures for recycling facilities to ensure that biofouling organisms or waste substances are not released into the local aquatic environment.

Summing up

Hull cleaning is essential for optimizing vessel performance and reducing fuel consumption. Although anti-fouling coatings initially prevent fouling, their effectiveness decreases over time, making regular hull cleanings necessary.

Recent technological advancements, such as ROVs equipped with high-pressure water jets, have enhanced safety and efficiency while prolonging the life of the anti-fouling coating.

However, hull cleaning poses a risk of releasing invasive aquatic species into the environment when conducted in water.

To mitigate this, vendors must comply with various port regulations concerning biofouling residues. Data has shown that after implementing a proactive approach to hull cleaning, each Odfjell vessel experiences a daily CO2 reduction.