The below is a copy of Odfjell’s content page on bbc.com: Odfjell (bbc.com)

How smarter ships are improving maritime transport

Innovation runs in the blood of Norway's oldest shipping company, Odfjell. Today, the group is bringing its time-honoured maritime expertise to the modern-day challenge of sustainability at sea.

The shipping industry keeps the global economy moving forward. It constitutes a significant part of the blue economy – the industries and livelihoods that are supported by our shared oceans. From household goods to food and raw materials, almost everything that we rely on in daily life has spent some time, in some form, travelling across the seas.

Watch the episode (article continues below):

Some national identities are inseparable from their maritime pasts. Norway, for example, is steeped in maritime history, with the sea explorations of the Vikings more than a thousand years ago and a dependence on the oceans for survival through centuries.

Today, the country is still one of the world's largest ship-owning nations, despite its relatively small size in geography and population. Among these ship owners is Odfjell. A family business founded over a hundred years ago, it is internationally influential in a global industry vital to modern life.

But shipping is facing some tough realities. In 2023, global cargo shipping in total contributed nearly 3% of the world's greenhouse gas emissions, more than that of the global aviation industry.

The need for shipping to innovate and adapt to reduce its impact on the environment has never been more urgent. And shipping companies themselves can play a pivotal role, something Odfjell is taking seriously as it expands its efforts beyond fuel to document significant emission reductions.

Established in 1914, as a family business with just one vessel, Odfjell was a pioneer in the chemical tanker trade in the 1950s having delivered the world's first stainless tanker, MT Lind, built at the Stord yard in Norway in 1960.

Now, its fleet of 70 ships sail the equivalent of about 200 times around the equator every year. Onshore in the USA, Belgium, and Korea, its terminals teams operate a total of 450 tanks with a capacity of 1.2 million cubic meters. Out at sea, its chemical tankers, which transport the raw materials used to produce many everyday goods, call into more than 400 different ports and transport 15 million tonnes of cargo every year.

VP Technology Erik Hjortland

While these raw materials, from chemicals to alcohols, also have their own carbon footprint, they are needed to make many household objects.

"The products we transport are the very building blocks for modern, everyday life," says Erik Hjortland, the vice president of technology at Odfjell. "Any sort of chemical, like the ones in your mobile phones, tablets, computers, cars, medicine, food – we transport the materials to producers who will use them to create those products you know and use every day."

Hjortland's family tree is filled with generations of mariners, almost all of whom built a livelihood from the ocean. "My great-grandfather and grandfather were both captains and ship owners. Both of my uncles are captains, and my father and his father worked at the local shipyard here in Bergen for many years.

"We take pride in our maritime heritage. I think that's had a profound effect on the DNA of the Norwegian people," Hjortland says. "We used to be a country of farmers and fishermen. We used to live and survive off the land and what the sea gave us. I think this has shaped us because nature and the preservation of it is important for us."

Captain Lise Henriksen together with her father in Nuvsvåg, Finnmark where she grew up.

Hjortland believes this historical reliance and respect for nature has also shaped attitudes towards the environment. Odfjell claims to be taking responsibility for its business's long-term effects on people and the planet. In 2020, it set ambitious targets to reduce its environmental footprint by reducing the carbon intensity of its operations by 50% by 2030, compared to their 2008 IMO-baseline, and to have a climate-neutral fleet from 2050.

The company has tested and implemented a wide range of operational measures and new technologies and tools to reduce emissions, among them propeller boss cap fins, propeller ducts, rudder bulbs, reversed osmosis plants, hull cleaning robots, ultrasound-technology on propellers, engine modifications, new propellers, energy efficiency alarm-systems – the list is long.

"We actively use data from all our vessels to monitor fuel consumption and emissions, and learn where we can save energy. Advanced weather routing, for example, ensures that our ships sail the safest, most energy efficient routes," he explains. These energy saving efforts extend below deck too. "Something as simple as automated lights in engine rooms which switch off when not in use has had a notably positive effect, too."

New propellers and boss cap fins are among the energy-saving devices Odfjell has implemented. Photo: Thomas Kohnle

Decarbonizing the industry and fully utilising green fuels for deep-sea shipping, however, will require more work than energy saving on board to achieve. Renewable electricity, Odfjell believes, is the key to the longevity of this goal.

"Decarbonizing shipping through green fuels will require a substantial amount of renewable electricity to produce the volumes of fuel that we are talking about here," Hjortland explains. "The deep-sea fleet will need around 50% of all renewable electricity available in the world today to produce the green fuels.

The production process for these alternative fuels is where Hjortland believes the biggest difference can be made. There is a huge amount of energy loss that happens when non-fossil fuels are made, which has seen Hjortland and his team pivot their efforts to energy efficiency and using existing technology to alter the emission curve.

Alongside this shift in focus, the Nordic shipping company is testing out new variations of energy saving measures on its ships and they continue to collaborate with partners across the sector.

"We are currently testing an air lubrication system called OceanGlide by Alfa Laval, which creates millions of air bubbles beneath the ship, reducing friction and drag," Hjortland explains, "which, if proven successful, reduces fuel consumption and CO2 emissions."

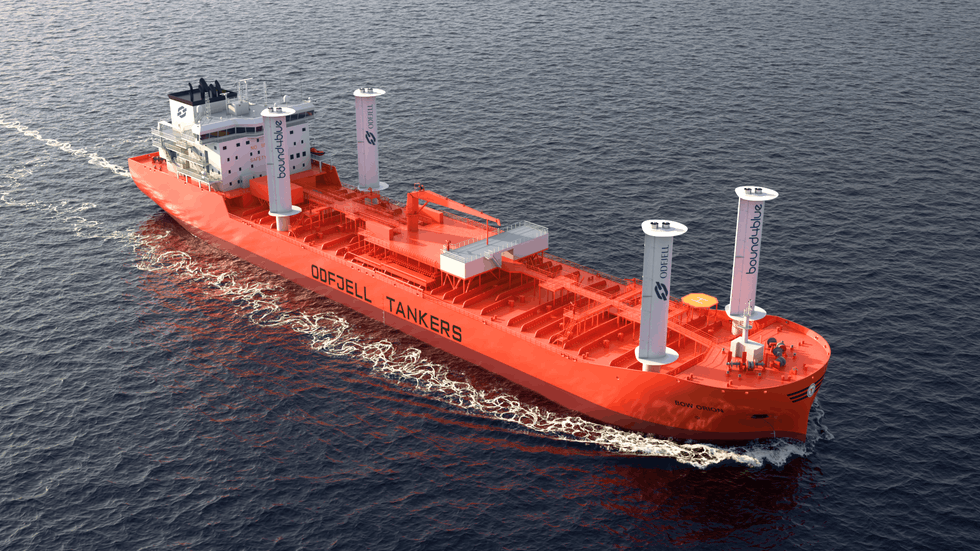

Animation of suction sail on a chemical tanker.

They're not stopping there, either. Later this year the company will pioneer the installation of suction sails, harnessing groundbreaking wind-assisted propulsion technology to launch the first tanker to make use of wind power through suction sails to reduce emissions. There are also plans to install the world's first zero emission capable and fuel flexible solid oxide fuel cell, which has the potential to reduce fuel consumption by as much as 50% compared to a standard combustion engine.

"We don't have to wait for a silver bullet," says Hjortland. "There are things that we can, and that we are, doing right now. We have to stop just talking about it. We have to act now by utilising existing technology that is available here and now."